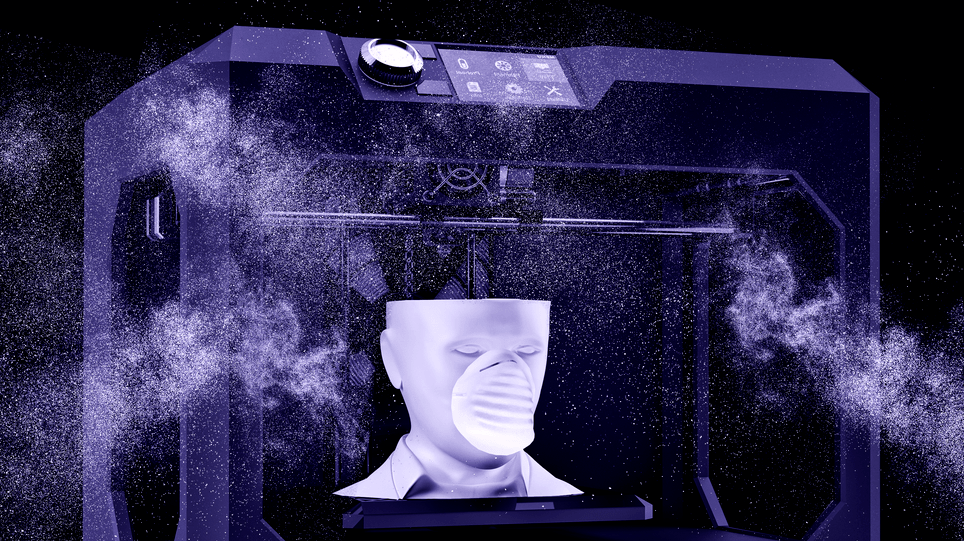

The smoke and particles generated by 3D printing may lead to respiratory issues

The smoke and particles generated by 3D printing may lead to respiratory issues

As of May 2024, 3D printed products are already in every home, and the manufacturing industry may have to adapt to using these new processes to meet demand. Since the emergence of 3D printing has given people a rich life experience, many families have more or less products such as 3D printers. People can diversify DIY items.

The global 3D printing market is expected to grow by more than 20% annually through 2024, according to a study, as consumer demand for 3D printing continues to increase and companies look for new ways to leverage these game-changing devices to advance manufacturing. to $17.5 billion. Fredonia Group. The market research firm predicts that most of the growth in the global 3D printing market will be concentrated in the United States, which will account for 42% of total sales in 2024.

Health Effects of Tiny 3D Printing Particles

As with other manufacturing processes that require heating plastic, 3D printing particles may be emitting harmful chemicals. In the case of these 3D printing particles, machines may generate small particles that can be embedded into the lungs, TechWorld reported. Researchers from the Illinois Institute of Technology (IIT) and France’s National Institute of Applied Sciences discovered that plastic 3D printing particles are less than 100 nanometers in diameter. Their small size makes them likely to be inhaled and travel into the lungs and brain.

Especially in environments with poor ventilation, its hazards will increase.

When a 3D printer is working, a variety of harmful substances will be emitted, such as volatile organic compounds (VOCs), particulate matter emissions, and harmful gas emissions. These harmful substances are invisible to the naked eye and remain for a long time.

- Volatile organic compounds (VOCs)

During the 3D printing process, molten plastic or other materials may release volatile organic compounds (VOCs). Long-term exposure to VOCs may cause symptoms such as headaches, eye irritation, difficulty breathing, and even damage to the central nervous system and internal organs.

- Particulate emissions

Microscopic particulate matter (PM) generated during the 3D printing process may be suspended in the air and inhaled by the human body. These particles may cause irritation and damage to the respiratory tract and lungs, increasing the risk of respiratory diseases such as asthma and chronic obstructive pulmonary disease (COPD).

- Harmful gas emissions

Some 3D printing materials will release harmful gases during the heating process, such as formaldehyde, ammonia, etc. Long-term exposure to these harmful gases may have serious effects on health and even increase the risk of cancer.

These small particles can cause inflammation in our respiratory system, or penetrate deep into our lungs and are small enough to enter our bloodstream,” Brent Stephens, lead author of the study and assistant professor of civil, architectural, and environmental engineering at IIT, told Techworld. “Once in our bloodstream, they may interact with our cells, or maybe deposited in sensitive areas such as bone marrow, lymph nodes, spleen, or heart. They can also access the central nervous system via our brains.

People may want to know about the risks of handling a plastic called acrylonitrile butadiene styrene (ABS), which produces ultra-fine 3D printing particles that are 10 times larger than another common 3D printing material, polylactic acid. When people are exposed to ABS, they may experience headaches and respiratory irritation. Researchers recommend 3D printing use specialized smoke evacuators with source capture when printing with ABS to prevent harmful side effects.

Fumeclear, as a professional air purification expert, has independent 3D printed source capture fume evacuators for washing. You can click here to learn about the product.